"MAMA IN and Six Sigma: Achieving Optimal Quality and Efficiency in Coffee Kit Production"

Share

"MAMA IN and Six Sigma: Achieving Optimal Quality and Efficiency in Coffee Kit Production"

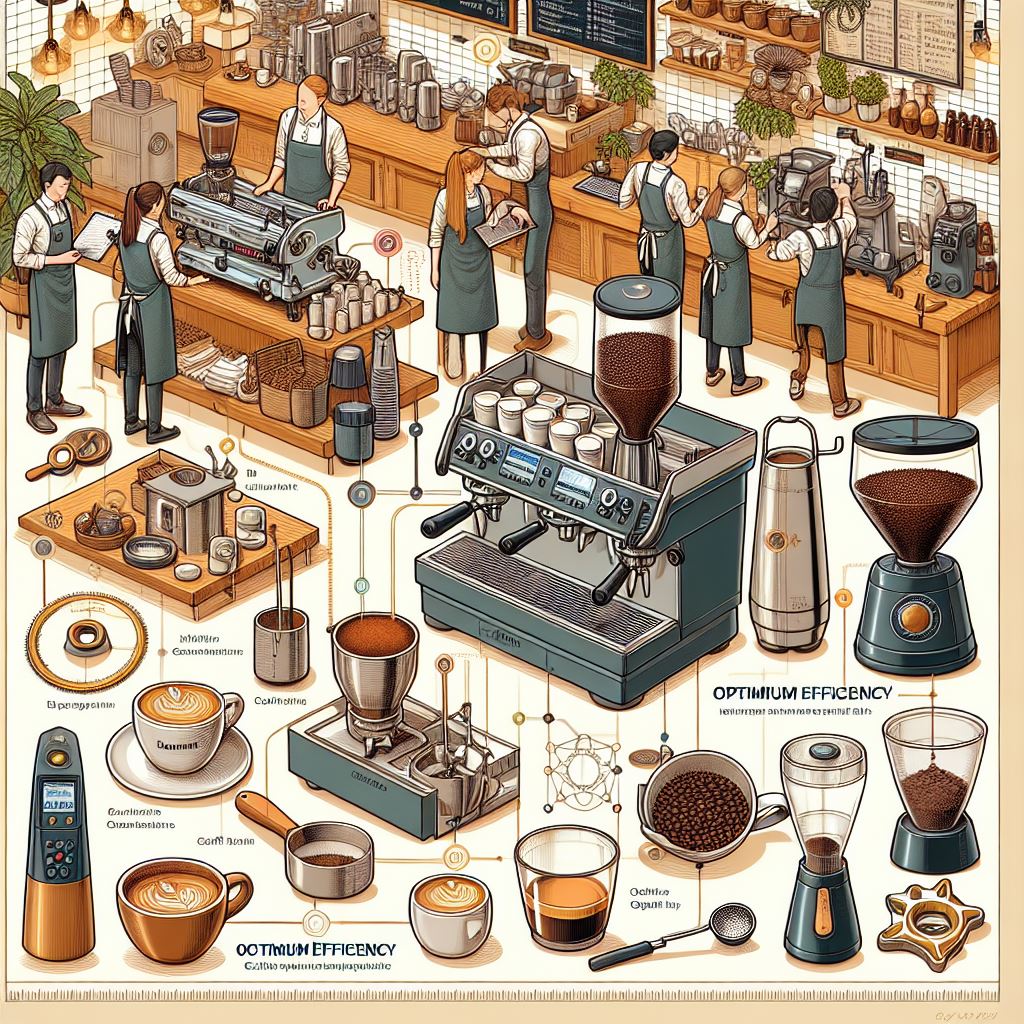

Introduction: In the world of coffee, where quality and efficiency intersect with scientific philosophy to achieve the perfect experience, MAMA IN stands out as one of the leading brands offering a meticulously designed coffee kit. By adopting Six Sigma methodology to enhance processes, MAMA IN aims to achieve the highest standards of efficiency and quality in every product. In this article, we will delve into the relationship between MAMA IN coffee kit and the Six Sigma methodology, which consists of five main phases: Define, Measure, Analyze, Improve, and Control, and how this approach can transform the coffee preparation experience into an art form.

- What is Six Sigma? Six Sigma is a methodology used to improve quality and reduce defects in manufacturing processes through a systematic and data-driven approach. It consists of five main phases:

- Define: Identifying the goals and customer needs.

- Measure: Collecting and analyzing data to measure performance and quality.

- Analyze: Understanding root causes of problems and defects.

- Improve: Modifying and designing processes to enhance performance and quality.

- Control: Establishing standards to ensure continuous optimal quality.

- Six Sigma and Its Application in MAMA IN Coffee Kit:

- Define:

- In this phase, MAMA IN sets clear objectives that align with customer expectations, such as improving the coffee experience, ensuring quality, and ease of use.

- MAMA IN defines these goals precisely to guide the design and development process, ensuring a product that meets the aspirations of all coffee enthusiasts.

- Measure:

- Precision tools are used to measure multiple aspects of coffee preparation, such as temperature, grind size, brewing time, and more.

- MAMA IN uses electronic scales to monitor quantities accurately and laboratory tests to examine raw materials to guarantee consistency in every cup of coffee produced (Stanford University, 2024).

- Analyze:

- In this phase, statistical analysis is employed to identify root causes of errors or defects in the kit. This may include analyzing material quality, design of the tool, or even usage methods.

- Through field studies, MAMA IN collects customer feedback and behavioral data to discover required improvements (American Society for Quality, 2024).

- Improve:

- MAMA IN uses the analysis results to refine the design of the kit, such as modifying the grinder design for easier operation, using better insulating materials to maintain coffee temperature, or even adjusting cup size to ensure a perfect brew.

- These adjustments are not merely cosmetic but are based on data and accumulated observations, enhancing the product's efficiency and performance (Harvard University, 2024).

- Control:

- This phase aims to ensure that production continues to meet the highest quality standards.

- MAMA IN is committed to monitoring the ongoing performance of the product, ensuring consistent quality with every use, through routine tests and performance monitoring (American Society for Quality, 2024).

- The Connection Between Six Sigma and MAMA IN: The link between Six Sigma methodology and MAMA IN products lies in how they achieve efficiency and consistency in coffee kit production. By integrating Six Sigma, which relies on data and process analysis, and MAMA IN’s attention to detail, it is possible to create a unique coffee experience for every user. This integration ensures that quality is not just about the components but also includes preparation, organization, and the surrounding environment.

- Continuous Improvement:

- Six Sigma contributes to the enhancement of manufacturing processes for MAMA IN coffee kit, reducing defects and increasing customer satisfaction. Research from Stanford University shows that companies adopting Six Sigma saw improvements of up to 35% in quality and a reduction in defects by up to 70% (Stanford University, 2024).

- MAMA IN uses this philosophy to conduct periodic improvements on the design and production based on customer feedback and data analysis.

- Efficiency Increase:

- Six Sigma techniques such as 5 Whys and DMAIC methodologies enhance efficiency.

- At MAMA IN, these techniques contribute to reducing waste and the time required to produce each piece, boosting overall kit efficiency and adding value to the customers (American Society for Quality, 2024).

- Reducing Variation:

- Six Sigma aims to reduce variation in the production process to ensure product consistency and quality across production batches.

- At MAMA IN, this philosophy translates into the use of tools and techniques aimed at ensuring each piece of coffee kit is produced with the same quality and performance (American Society for Quality, 2024).

- Statistics and Studies:

- A study published by Harvard University showed that companies adopting Six Sigma saw improvements of up to 50% in customer satisfaction and an increase in worker productivity by up to 30% (Harvard University, 2024).

- According to the American Society for Quality, products undergoing Six Sigma process enjoy a defect-free rate of 99.99966%, enhancing customer trust in MAMA IN products (American Society for Quality, 2024).

- Benefits of Applying Six Sigma to Coffee Kit Production:

- Achieving Harmony: Through Six Sigma, MAMA IN ensures harmony among all components of the kit, from grinder and heater to insulated cup. Each element is designed to support the others, providing a unique coffee experience for every user.

- Quality Control: MAMA IN adopts Six Sigma methodology to improve quality control processes, reducing errors and increasing consistency in every coffee preparation. These measures directly enhance the coffee experience and increase customer satisfaction (Stanford University, 2024).

- Waste Reduction: Through precise analysis and data usage, MAMA IN reduces waste and increases efficiency, reflecting its commitment to high-quality standards (American Society for Quality, 2024).

- Conclusion: By embracing Six Sigma, MAMA IN elevates its ability to deliver a coffee kit that not only reflects high quality and efficiency but also exceeds expectations to become a benchmark for the perfect coffee experience. Whether brewing at home or in the office, MAMA IN ensures that every cup of coffee is prepared with precision and the highest standard of efficiency, making every moment of coffee a special and unique one.

Sources:

- Stanford University. (2024). Improvements in quality using Six Sigma. Source: Stanford University.

- American Society for Quality. (2024). High-quality products using Six Sigma. Source: American Society for Quality.

- Harvard University. (2024). The impact of Six Sigma on customer satisfaction and productivity. Source: Harvard University.